Welding & Plateshop

Activities

Welding & Plateshop in general, with emphasis in the chemical, petrochemical, pulp and paper and related areas.

Welding & Plateshop in general, with emphasis in the chemical, petrochemical, pulp and paper and related areas.

- API Tanks;

- Pressure Vases;

- Air ducts and gas ducts;

- Steel Structures;

- Boiler pressure parts, such as tube panels, distribution collectors , oil burning devices, etc;

- Auxiliary high-pressure pipes;

- Dampers with mechanical or automatic switch.

Welding & Plateshop Capacity

- Clad Welding – Ø 1000 x 1000 mm (high) – turning table 10 ton;

- Waterjet Cutting – 8” x 1800 x 3600 mm;

- Oxyfuel Cutting – 8” x 3000 x 6000 mm with High Definition Plasma Cutting – until 1.1/4” X 3000 x 6000mm;

- Hydraulic Rolling Machine – 7/8” x 2500 mm;

- Hydraulic Rolling Machine – ½” x 2500 mm;

- Hydraulic Shearing Machine – ½” x 3000 mm;

- Hydraulic Bending Machine – ½” x 3000 mm;

- Several Welding Machines – Electrode, MIG and TIG;

- 2 Cranes – 10 Ton.

Waterjet Cutting

Aiming to offer differentiated services, we acquire a “Flying Bridge” from Flow, company world-wide Leader in this segment.

This innovation offers innumerable advantages:

- Cold Cut, not presenting thermally affected zone.

- Final touch with quality, facilitating the process of Machining, optimizing the time of production and minimizing costs.

See a table Advantages of Waterjet cutting over other cutting processes »

Examples:

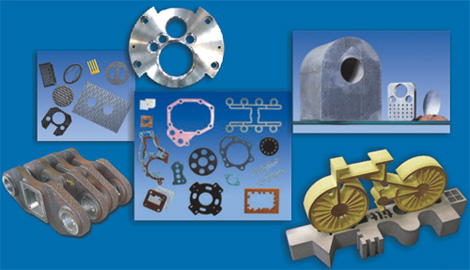

Bellow, some of the products that can be produced by Flying Bridge: